While discussing the various fabric inspection systems for garment manufacturing, Nitika Rana affirms that of all systems, the 4-point inspection system has got wide acceptance and is adopted globally by fabric and garment manufacturers.

- 4 point system fabric inspection

- 10 point system fabric inspection

- 4 point system fabric inspection report format

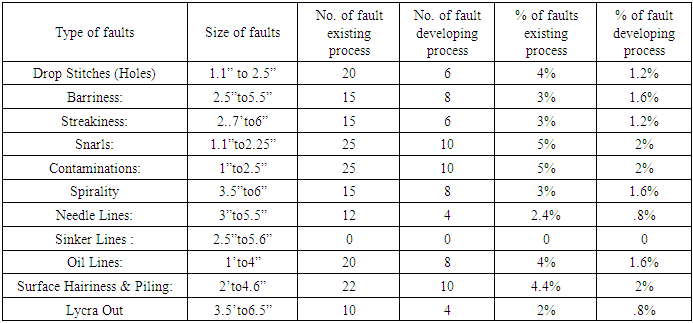

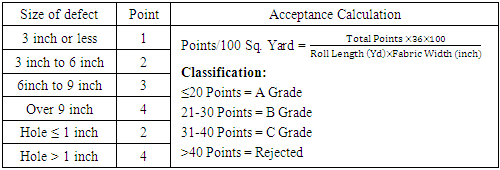

During inspection, following points are considered Knitting fault Point Slub 1 Any hole 4 Needle/Sinker line 4 Needle breakage(up to 10) 4 Press off 4 Thick, Thin, Dirt, Oil spot, Contamination up to 3″ in length 1 Thick, Thin, Dirt, Oil spot, Contamination up to 6″ in length 2 Thick, Thin, Dirt, Oil spot, Contamination up to 9″ in length 3 Thick, Thin, Dirt, Oil spot, Contamination above 9″ in length 4 Quality (points per 100 square meter) = (Total point X GSM)/ (Roll weightX10) Quality Classification: After calculation of the quality of the knit fabrics, decision is delivered according to the following way.. There are various fabric inspection systems such as- • 4- point system • 10- Point system • 2.. Latest posts by Md Omar Faruk () • - July 5, 2018 • - June 27, 2018 • - May 9, 2018 Fabric Inspection| Four Point System Inspection: Inspection can be defined as the visual examination of raw materials (such as fabric, buttons, zippers, sewing threads, trims etc), partially finished components of the garments and completely finished garments in relation to some standards, specifications or requirement as well as measuring the garments to check if they meet the required measurements.

4 point system fabric inspection

4 point system fabric inspection, 4 point system fabric inspection formula, 10 point system fabric inspection, 10 point system fabric inspection ppt, 4 point system fabric inspection report format, 4 point system knit fabric inspection formula, what is called the 4 point system in fabric inspection, 4 point system woven fabric inspection, what is four point system in fabric inspection, 4 point system textile inspection, 4 point system knit fabric inspection Arma 3 Mac Download Free

In; most of the companies follow four point systems for measuring the quality of the knit fabric.. Following table shows the four point grading system followed by inspection at different knitting mills. FLV Converter SDK download free for windows 8 64bit last version

10 point system fabric inspection

4 point system fabric inspection report format

After knitting; are gathered in front of the checking table and the quality inspector inspect the quality of the knit fabric and listed the found in the knit fabric and mark it in the knit fabric.. Fabric Inspection Using Four-Point System Inspection: Using 4-Point System or any other agreed upon system as defined by the customer, inspection is carried out.. 1 2 3 30 OK Ask Reject So, when we will check the quality of the knit fabric, we should follow the four point systems.. There are various methods for measuring quality of the knit fabric but among all of the methods four point systems is preferable to the inspector of the quality.. Four-Point System: Four-Point System, a standard established under ASTM D5430 – 07(2011), is a standardized Test Methods for fabric Visually Inspecting and Grading.. Four (4) – Point system for knitting fault inspection: During inspection, if the inspector found any knitting faults then he marks it in the fabric and counts it in the sheet. cea114251b

0 kommentar(er)

0 kommentar(er)